Traction Elevator

Manufacturers

- Home

- >

- Traction Elevators

Products

Traction Elevator

- Traction elevators are steel roped elevators that are looped around the electric motor of the elevator.

- The steel ropes are used for raising and lowering the elevator. Traction elevators are also known as electric elevators.

- Traction elevators are more widely installed in commercial establishments than in residential establishments.

- The belts in the traction elevator use flat seat belts or conventional steel ropes. Belts are wound around the electric motor that turns into sheaves.

- Buildings with the high raised establishment install traction lifts because the energy consumption is very low.

- The steel rope is used as a pulley to counterweight the weight of the elevator. The steel rope in the elevator rises and lower the elevator.

Installation

Modernization

Maintenance

Cost Effective

How do traction lifts work?

Traction elevator works based on the cable looped upon the machine. The motor has a sheave attached; the sheave works when the rope or a pulley is comprised in it. As the sheave spins the pulley moves the elevator cabin moves accordingly. One end of the car lift is attached to the rope and the other is to counterweight the weight of the elevator. The sheave is turned on by the motor when the elevator car moves towards the down floor.

The motor that moves down, travels in two directions one moves the elevator car and the other towards the downward. This is how the traction elevator works. The size and dimensions of traction lift vary according to the establishment. Emperor Lifts is known for the best quality elevators and thus making us one of the best traction lift manufacturers in Bangalore.

Types of Traction lifts

Geared

- Geared traction elevator uses a gearbox attached to an electric motor to move the elevator car. The worm and gear-type reduction unit in the electric motor drives the elevator.

- The reduction motor turns the hoisting sheave. The advantage of the reduction unit is that they require less power motor when compared to the sheave.

- We customise elevators for the capacity of 6, 8 and 10 passengers. The electrical brake in the geared traction plays a major role.

- Electric brakes between the motor and reduction unit stop the elevator, maintaining the car at the desired floor height.

Gearless

- Gearless traction elevators do not have any gearbox attached to the elevator car. In a gearless traction elevator, the sheath wheel is directly attached to the motor. Gearless traction machines are usually installed in commercial establishments.

- Establishments that are raised high and have multistorey floors install gearless elevators because they travel higher speed than the steam-powered elevator.

- By pushing the cables into the grooves on the drive sheave, the elevator car and counterweight give the drive sheave the necessary traction. The load of the motor can be reduced by measuring the weight of the car.

- The governing device provides safety by engaging the elevator car brake thus gearless traction machines are safe to install in high raised commercial establishments.

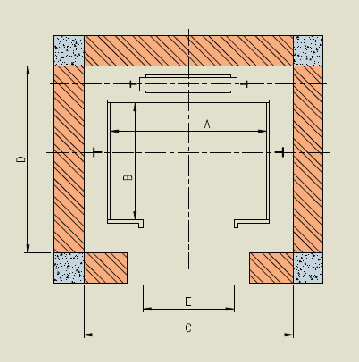

- The depth of the elevator car ranges from 900 mm to 1300 mm and the width of the car ranges from 1200 mm to 1400 mm

- The Vertical movement of the lift car is enabled by an enclosure with unobstructed space called a lift well.

- The width of the lift well in an elevator ranges from 1650 mm to 1900 mm and the depth ranges from 1525 mm to 1900 mm.

- We customise and install high-quality traction lifts in Bangalore for our customers.

Machine Room-less Traction lift

- Machine Room Less elevators are specially designed elevators that are installed without any machine room.

- Machine roomless elevators are directly placed near the hoistway. The elevator moves on the steel cord cableway just like other elevators.

- The frequency converter combines with the synchronous motor. The MRL elevator operates on the principle of a gearless synchronous motor and a traction induction VVF motor.

- The headroom for a traction elevator ranges from 4575 mm to 4880 mm. The counterweight assists the machine in turning the electrical sheave which moves the cab through the hoistway.

- The standard features of a machine room-less elevator include emergency alarm, independent operation, automated monitoring system, time & temperature delay and intercom facility.

- It works based on the gearless traction machine which is located near the hoistway.

Specifications

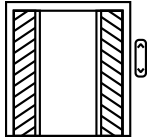

Doors – Automatic/Manual [Automatic – mild steel, stainless steel

Manual – ms imperforated door, ms telescopic

Cabin – Mild steel, wooden, stainless steel

Features

| CAPACITY | DOOR | CAR INSIDE | LIFT WELL | ENTRANCE | HEAD ROOM(H) | |||

|---|---|---|---|---|---|---|---|---|

| WIDTH | DEPTH | SHAFT WIDTH | SHAFT DEPTH | SHAFT WIDTH | SHAFT DEPTH | |||

| 6 Passenger (408kgs) | MANUAL | 1200 | 900 | 1650 | 1525 | 700 | 700 | 4575 |

| AUTOMATIC | 1200 | 900 | 1650 | 1550 | 700 | 700 | 4575 | |

| 8 Passenger(544kgs) | MANUAL | 1200 | 1200 | 1700 | 1800 | 800 | 800 | 4880 |

| AUTOMATIC | 1200 | 1200 | 1830 | 1830 | 800 | 800 | 4880 | |

| 10 Passenger(544kgs) | MANUAL | 1400 | 1300 | 1900 | 1900 | 800 | 800 | 4880 |

| AUTOMATIC | 1400 | 1300 | 1900 | 1950 | 800 | 800 | 4880 | |

| CABIN HEIGHT | CLEAR OPENING HEIGHT | BELOW LINTEL HEIGHT FROM FINISHED FLOOR LEVEL |

|---|---|---|

| 2200 | 2000 | 2250 |

| 2300 | 2100 | 2350 |

Types of suspension ropes

Wraping for traction sheave

Single Wrap

Double Wrap

- In Single wrap, the sheave has the rope passing over to counterweight the sheave and rope connection.

- The single wrap is used in mid and low-speed elevators with geared traction machines.

- In a double wrap, the sheave has rope passing twice so that the elevator speed is high.

- And adds additional friction to the gearless traction motor. The double wrap is used in high-speed elevators.

Roping Method

There are two types of roping methods. They are 1:1,2:1 and 4:1 roping methods.

Type 1

Type 2

- The 1:1 roping method is installed in high-speed elevators and geared traction elevators.

- The 1:1 rope is connected to counterweight the cable car in the opposite direction.

- The 2:1 roping method is connected to the top of the shaft.

- 2:1 roping method is used in gearless traction, freight elevator, bottom drive and gearless traction machine.

Benefits of Traction Lift

- When compared to hydraulic elevators, traction elevators are efficient and reliable.

- The mechanical operation is less in the case of a traction elevator.

- The requirement of space in the gearless traction elevator is less when compared to other traditional elevators.

- They travel faster when compared to hydraulic elevators. Thus they can be installed in commercial establishments and multistorey buildings.

- The gearless traction elevator travels smoothly and is reliable.

- The cost of installing a gearless traction machine is cost-effective.

- The traction machine has the accommodation of front and rear openings.

- Traction lifts are designed for small and mid-sized buildings, multistory buildings and commercial establishments that install traction elevators in Bangalore.

- There is no risk of oil contamination in traction lift

- Traction elevator can be driven by alternating current or direct current.

- The gearless traction elevator has both manual and automatic doors.